Grading of nanocellulose using a centrifuge

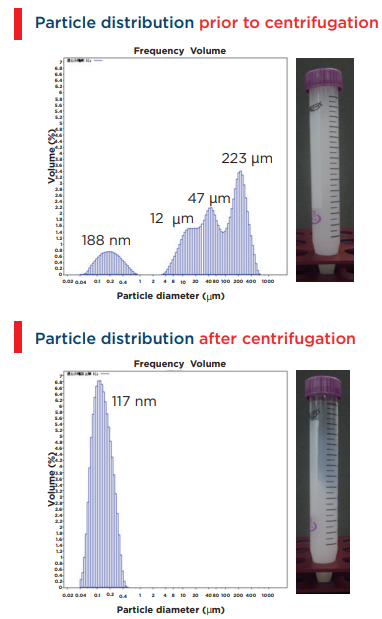

Nanocellulose is a nanomaterial that is garnering attention recently, and it is obtained from cellulose or a cellulose derivative through wet-type high-pressure dispersion and pulverization or wet-tye grinding and pulverization. We will introduce the results of particle size measurements made using a Laser diffraction / scattering method particle size distribution measurement apparatus LS 13 320 to measure nanocellulose that was obtained by performing wet-type high-pressure dispersion and pulverization on low-substituted hydroxy propylcellulose, which is one type of cellulose derivative, as well as the results for separation of only the component to be measured in the nanosize region through centrifugation.

A Shin-Etsu Chemical Co., Ltd. L-HPC (low-substituted hydroxy propylcellulose) LODICEL LDC-H 2 wt% dispersion was passed through a Sugino Machine Ltd. Starburst test apparatus 10 times at a pressure of 150 MPa for use as the dispersion in the experiment.

After using a high-speed refrigerated centrifuge (Avanti JXN-26) and a fixed angle rotor (JA-14.50) to centrifuge the material at 14,000 rpm (35,000 xg) for 1 hour, the supernatant was collected and the particle diameter was measured. As a result of the centrifugation processing, it was possible to isolate and recover only the component consisting of the nanosize particles. The particles measured to be 188 nm prior to centrifugation were measured as 117 nm after centrifugation. This could be because, when there is polydispersion, the smaller particle diameter values will tend to approach the larger particle diameter values.